Industrialization

Industrial excellence driving productivity

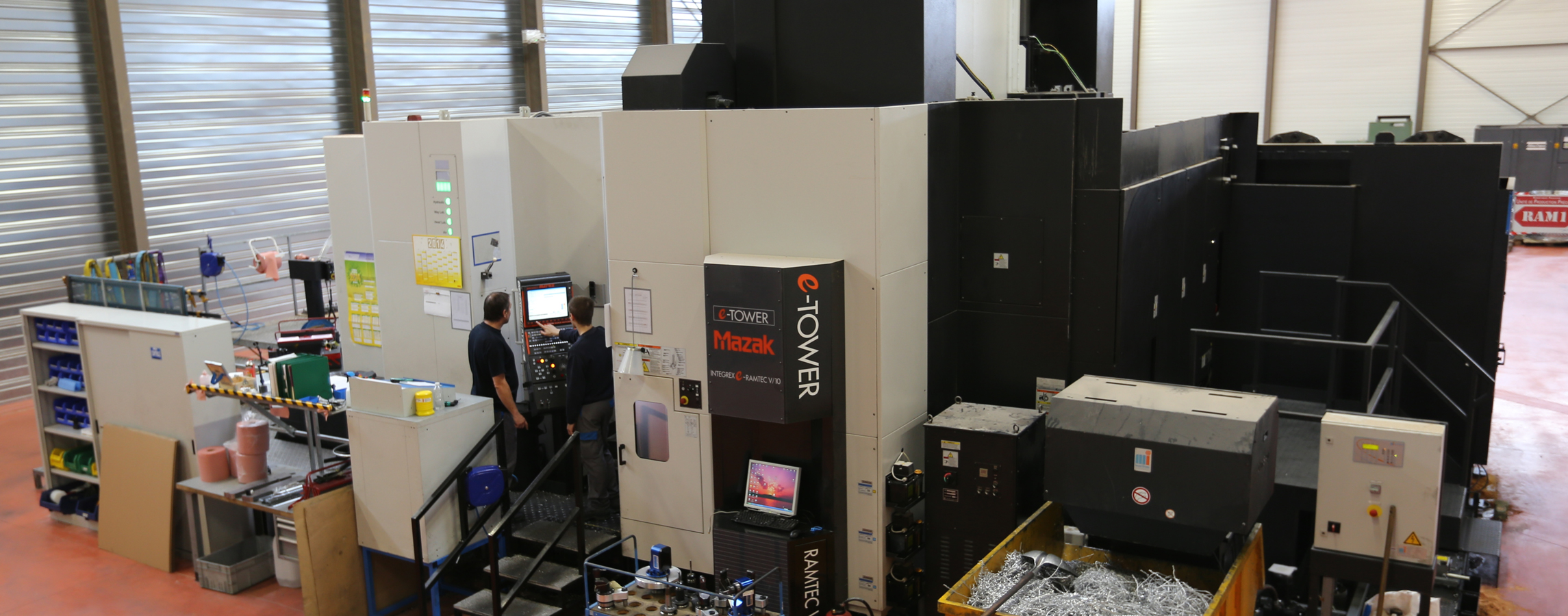

Precision mechanics is at the heart of Figeac Aero's business. It requires significant fine-tuning of production processes for aluminium and hard metal machining. To ensure high-level performance, and guarantee competitiveness, Figeac Aero's technical services (Methods Engineers - CN Programmers) design customised production processes for each part to make the most of the potential of the machine/cutting tool/part positioning tools combination.

During this phase, in which the Company has over 20 years of experience and has produced over 10,000 different references, machining simulations are carried out with the VERICUT software package. The tools are managed with GEDIX and cutting parameters are optimised with SIM-MIL and ACCORD-MIL to ensure the viability of the process.

Many criteria are taken into account, including temperature, materials deformation, lubrication, wear and tear on cutting tools, etc.

Human expertise provides an advantage

This theoretical approach is then put into practice on the machines with tuners/adjusters dedicated to working with operators in the workshop to ensure the successful fabrication of the first part. The part then undergoes quality control via an FAI (First Article Inspection) process.

Figeac Aero is able to implement a significant industrialisation volume each year. This has enabled the Company to grow substantially. This theoretical and practical knowledge base allows the Group to direct its machine investment and R&D judiciously toward future issues such as cutting tool optimisation to increase its leading position.

The specialised production workshops are set up to comply with Lean Manufacturing best practices and 5S to guarantee a high-performance working environment.